Dynamic, accurate & reliable: KOSTAL variable frequency drives for roller bearing drives

KOSTAL INVEOR MP: motor-mounted performance for azimuth roller bearing drives

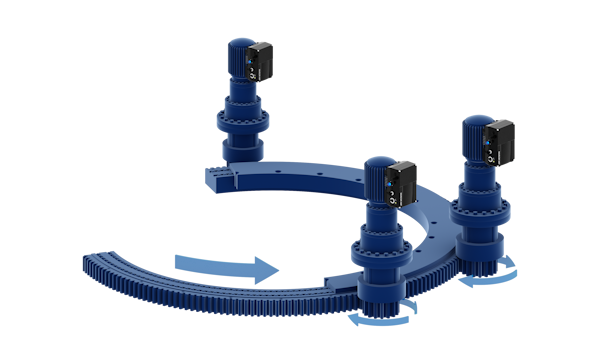

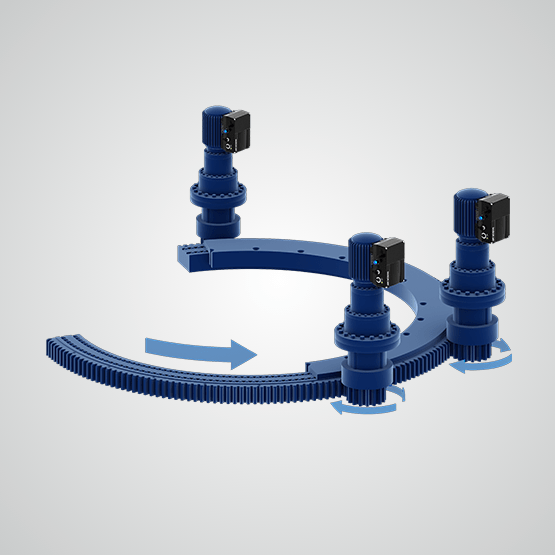

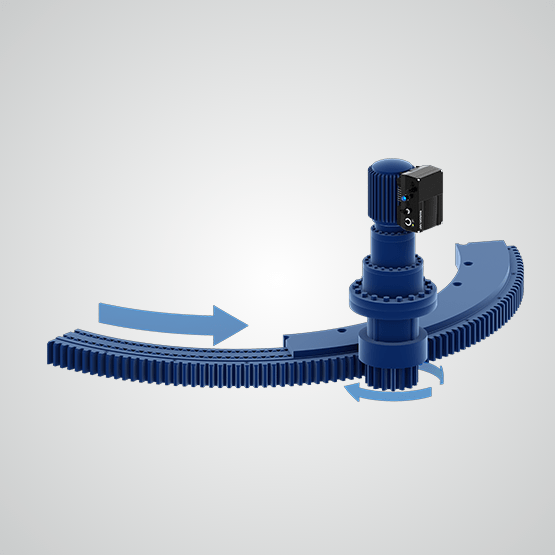

In modern wind turbines, electric motors are used in the azimuth drives, which align the turbine house perfectly with the wind. Depending on the size of the turbine, up to eight geared motors drive these roller bearings. Synchronous control and even distribution of power to all motors are particularly important here.

With the KOSTAL INVEOR MP variable frequency drive, you get an excellent control unit for azimuth roller bearing drives. The design of the variable frequency drive allows a direct connection to the motor. Once installed, it forms a fixed unit with the roller bearing drive via the adapter plate.

The absence of electrolytic capacitors in the INVEOR's power electronics as well as its control technology, which features no sensors at all, guarantees reliable and low-maintenance operation in this environment.

Robust, functional and communicative: KOSTAL variable frequency drives for pitch systems

In a wind turbine, pitch systems regulate the output of the turbine via the position of the rotor blades in relation to the wind. This allows the efficiency of the turbine to be adjusted perfectly to the prevailing wind strength. In a similar fashion to the azimuth drive, a pitch system is also driven by gearmotors. Precise positioning and the ability to adapt quickly to changing wind conditions are important requirements.

Our INVEOR MP variable frequency drive impresses customers with its sensorless positioning and a highly dynamic control process. Its good reliability guarantees high system availability and long maintenance cycles.

Do you have any questions about our KOSTAL variable frequency drives for roller bearing drives?

Then complete our contact form or give us a call. We will answer your questions and help you to implement the right solution in your company.

KOSTAL support for new and potential customers

KOSTAL Industrie Elektrik GmbH & Co. KG / Business Unit Drives

Lange Eck 11

58099 Hagen, Germany

+49 2331 8040 - 468 sales-industrial@kostal.com