Control compressors more efficiently with KOSTAL variable frequency drives

Energy-saving compression with smart KOSTAL INVEOR variable frequency drives

A variable frequency drive that regulates a compressor’s electric motor controls more than just the speed. It optimises energy consumption too. Because the more precisely the variable frequency drive regulates the input voltage and adapts it to your application processes, the less energy it consumes. This saves money and is good for the environment.

With motor-mounted KOSTAL variable frequency drives, such as the INVEOR MPP or the INVEOR MP, you now have a drive controller that perfectly adapts the motor speed of your motors to your processes. And without having to sacrifice performance. In this way, you reduce your energy bills and at the same time benefit from greater efficiency in your company.

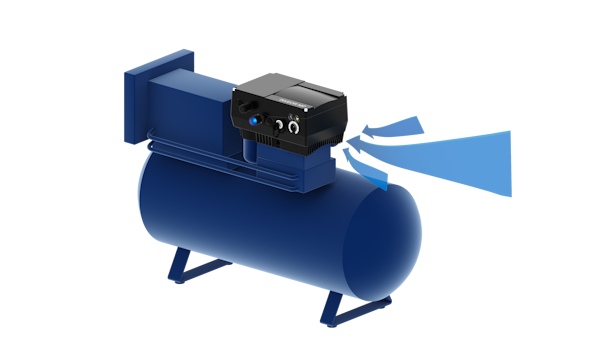

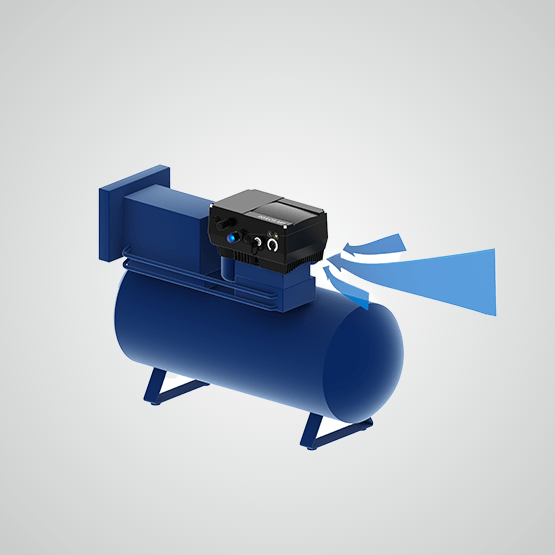

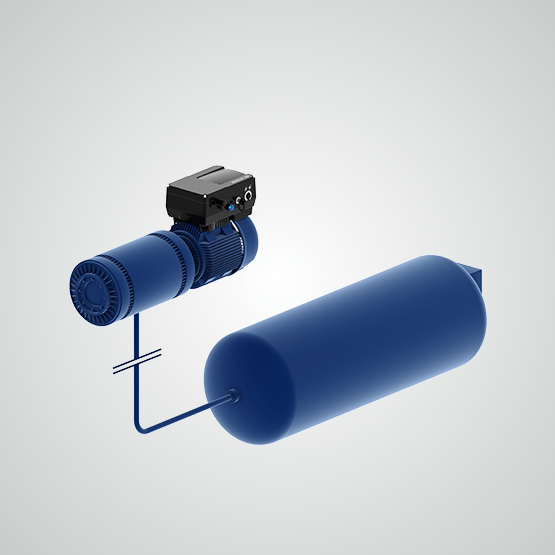

Piston compressors with KOSTAL INVEOR variable frequency drives: Optimum reliability

Compressors, such as reciprocating piston compressors, almost always generate high levels of vibration. These can cause damage to adjacent devices, including a variable frequency drive. That is why it is important that the drive controllers you use can withstand the inherent vibrations of a reciprocating piston compressor.

The KOSTAL INVEOR MPP is a motor-mounted variable frequency drive with which you can easily control the electric motor of a reciprocating piston compressor. This is because its robust die-cast casing ensures optimum vibration resistance. By dispensing with electrolytic capacitors, we were also able to minimise maintenance requirements. For unprecedented reliability.

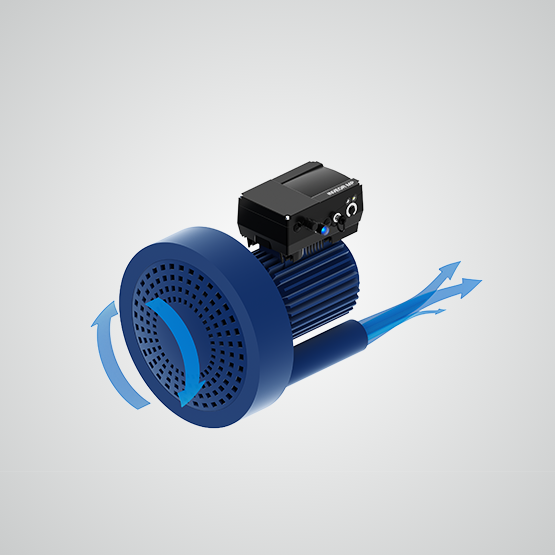

Brake compressors with KOSTAL variable frequency drives: Safe functioning at all times

Brake compressors in buses and trucks ensure that they come to a stop in good time. However, constant vibrations in road traffic complicate the conditions under which the brake compressor's drive controller has to do its work.

With the KOSTAL INVEOR M drive controller, vibrations are no longer an obstacle. This is because the motor-mounted variable frequency drive is not at all affected by even the most violent jerking and shaking thanks to its robust housing and sensorless control.

The compact construction also allows seamless integration into your application, while our smart control process ensures optimum energy efficiency.

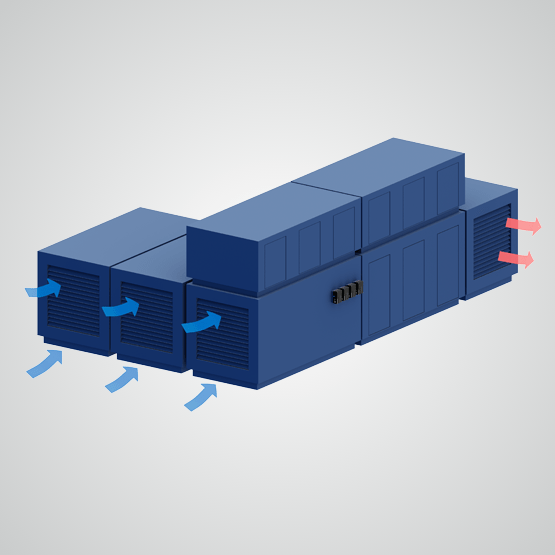

Large refrigeration systems and KOSTAL INVEOR variable frequency drives: Great reliability with maximum energy savings

Large refrigeration systems are often found in industrial food production. Here, precise and reliable temperature regulation is essential for processing sensitive foods. The cooling capacity, designed for maximum demand, needs to respond flexibly to changing environmental conditions and seasonal fluctuations.

Particularly in partial load ranges, the KOSTAL variable frequency drive helps to save a large proportion of the energy. With its smart master-slave control, it ensures optimum adaptation of device performance to actual requirements. This extends the service life of the system and the INVEOR MP, with its low-maintenance operation and robust design, ensures a high level of system reliability.

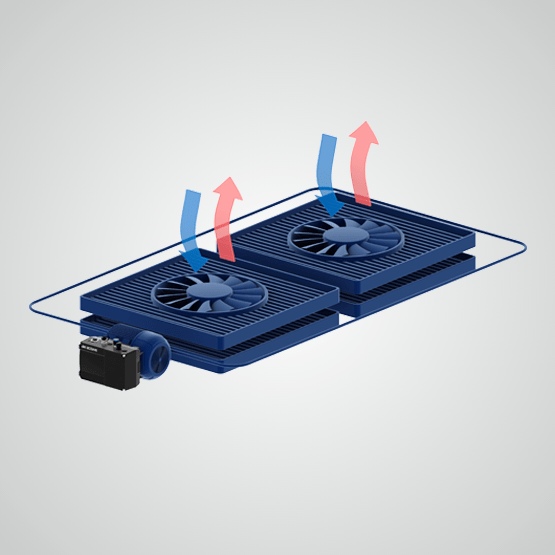

Roof-mounted air conditioning systems and KOSTAL variable frequency drives: Optimum operation even under adverse conditions

Refrigeration compressors are indispensable. They compress gaseous refrigerants and thereby ensure optimum temperature conditions – even in the field of mobile applications. However, these are applications which often experience high levels of vibration and large temperature fluctuations. This makes using the right variable frequency drive essential for optimum operation.

Vibrations and extreme temperatures are not a problem for KOSTAL INVEOR M variable frequency drives – thanks to their robust die-cast casing, IP 65 protection class and an extended temperature range from -40 °C to 50 °C. To also optimise the battery life of your mobile applications, it is also optimised for energy efficiency. The starting torque remains unaffected – for optimum operation, even in adverse conditions.

INVEOR Coldplate solution for heat pumps: Control of all motor types with maximum efficiency

KOSTAL also demonstrates its problem-solving expertise in the field of booming heat pump technology. Motors that are complicated to control and tight installation space place special demands on a frequency inverter. Since a converter with its own housing is not necessarily required inside the heat pump housing, KOSTAL offers a coldplate solution here that is very

a coldplate solution here that can be compactly integrated into the heat pump using existing thermal sinks. In this area, too, the INVEOR frequency converter benefits from the fact that it controls all motor types, including reluctance motors, reliably and with maximum efficiency.

Do you have any questions about our KOSTAL variable frequency drives in compressors?

Then complete our contact form or give us a call. We will answer your questions and help you to implement the right solution in your company.

KOSTAL support for new and potential customers

KOSTAL Industrie Elektrik GmbH & Co. KG / Business Unit Drives

Lange Eck 11

58099 Hagen, Germany

+49 2331 8040 - 468 sales-industrial@kostal.com